Nanjing Jiaqiang Jiushi Technology Co., Ltd., established in 2005, traces its origins to an IT service enterprise jointly founded with the Nanjing Railway Sub-bureau. Over the years, the company has developed into a comprehensive technology enterprise integrating R&D, manufacturing, sales, and service, with business areas covering rail transit, electrical equipment, and intelligent applications.

The company has long been committed to providing high-performance products and services for the manufacturing and operation of rail transit equipment worldwide. Driven by technological innovation, it has established an R&D system covering intelligent control systems, automated electrical equipment, data analytics, and safety assurance. Leveraging deep industry expertise and continuous technological investment, multiple self-developed core products have been successfully applied in major projects both domestically and internationally, delivering efficient, stable, and intelligent solutions for clients. Among them, the self-developed circuit breaker auto-reset device has been reliably deployed in fully automated driverless metro trains in several cities, ensuring operational safety and reliability, while various intelligent boards have been successfully applied in multiple railway digitalization projects across China.

In terms of international collaboration, the company has established close partnerships with globally renowned enterprises, gaining extensive experience in international supply chain integration and technical services.

Throughout its growth, Nanjing Jiaqiang Jiushi Technology Co., Ltd. has continuously optimized its R&D processes, improved its quality management system, and focused on transforming technological achievements into practical applications, forming a complete capability chain from solution design and product manufacturing to operation and maintenance services. Looking ahead, the company will continue to lead industry upgrades through innovation, earn market trust with quality, and strive to become a leading brand in the fields of rail transit and intelligent technology.

Conceived by Mr. Wang Xiaojun, the solution builds on a rail-specific edge-computing architecture that integrates “remote equipment monitoring, intelligent circuit-breaker reset, status analytics and fault prediction” into a single train–ground collaborative system, ready for fully driverless networks.

Architecture

Edge nodes on the train work with a cloud-based ground platform; on-board intelligent modules and the wayside supervisory system jointly deliver real-time monitoring and closed-loop control of circuit-breakers, power-supply equipment and other critical on-board assets.

Core Functions

· Remote, self-resetting circuit-breaker system – safeguards unattended train operation

· AI-driven condition monitoring & predictive-maintenance engine – real-time fault warning and maintenance-policy optimisation

· Intelligent operation-control platform – end-to-end visibility and control of train–ground assets

· Power-supervision & smart energy-management module – raises energy efficiency and safety levels

Technical Advantages

· Automates maintenance tasks and cuts manual inspections

· 60 % faster fault clearance; equipment availability up > 30 %

· City- and line-agnostic unified supervision and smart dispatching

· Open architecture with standard protocols for multi-system integration

Field Performance

Deployed in Nanjing, Suzhou, Guangzhou, etc.; accumulates 300 million safe-kilometres, enabling GoA4 autonomous operation and intelligent O&M upgrades.

Outlook

Scalable across metro, high-speed rail and light-rail networks with strong export potential. Continuous R&D will advance the industry toward “smart O&M + green energy + remote cooperative control”.

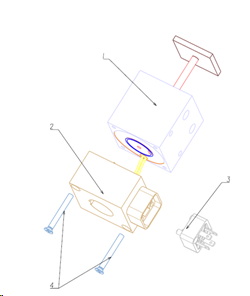

The remote reset device produced by our company achieves the reset function of the on-board

circuit breaker through remote control by transmitting signals via the train

The remote circuit breaker reset device is a crucial vehicle safety equipment, which can enhance

the safety and reliability of train operation, especially in fully automated

driverless trains. When a short-circuit fault occurs and the circuit breaker fails to automatically

close after resetting, the remote reset function ensures the normal operation

of the train and prevents train downtime caused by circuit breaker issues.

The design and implementation of this remote reset device not only enhance the automation

level of train operation but also strengthen the monitoring and control capabilities over

the train's operating status, which is of great significance for ensuring the safety of train operation